Thus the additional EC layer around the BP and WH papers resulted in the enhanced tensile index and strength. The method for testing the tensile strength of plastics is the same as that of metal.

Polymers Free Full Text Natural Polymeric Materials A Solution To Plastic Pollution From The Agro Food Sector Html

However the elongation values of the bioplastic fluctuated for the white egg plasticizer.

. I took a few different kinds of plastic both bio and petrol and tested the weight it took to break them. For elongation property of the bioplastic both glycerol and sorbitol as many as 28 will decrease the elongation value 328 and 161 respectively. The ultimate strength of the bioplastic was then measured and calculated by the aforementioned equation.

Therefore bioplastics are sustainable largely biodegradable and biocompatible. To do this I took three kinds of plastic ABS PLA and a homemade. It is worth noting that the bioplastic in question was originally designed to package beef in the form of hamburgers which are vulnerable to microbial contamination and have a strong smell but the principle of adding nanoclay.

CONCLUSION Bioplastic film can sustain the weight near about 2 kg and which have enough tensile strength. Whereas with the addition of the egg white the tensile strength of the bioplastic is increased to 49. Using a Dog-Bone test specimen and recording the yield point.

Improved tensile strength of glycerol-plasticized gluten bioplastic containing hydrophobic liquids Bioresour Technol. The composite bioplastic is stronger than starch bioplastic with increased tensile strength and reduced elongation. The lowest tensile strength 165 MPa was recorded for bioplastics with the highest glycerol concentration 60 whereas the highest.

Sole EC film has a tensile strength of 4772 MPa McKeen 2012 higher than the tensile strength of the uncoated papers in this study. Most commercial high-purity grades are semicrystalline have high transmittance 90 and high yield and tensile strength. The DS of 06 resulted in a bioplastic with a tensile strength of 842 MPa a solubility of 2031 g100 g and a WVP of 234 10 7 gmm 2hPa.

The degree of substitution DS of 06 was the most promising compared to the DS of 11. Conventional polyethylene packaging has less than half this tensile strength in the range of 20 MPa30 MPa. Environmental performance of bioplastic packaging on fresh food produce.

For the second strength test Strength Test B each bioplastic was secured at one end by a weight and at the opposing end attached to clips and pulled by a spring balance shown in figure 2. My experiment involves testing the strength of plastics and bio plastics - specifically the tensile strength or the amount of force they can take before they break. Elongation at break.

Common plastic production and use have become one of the driving forces behind climate change due to unprecedented world pollution of land and sea. The Surface Response method is proposed for optimizing composition materials which are used. Bioplastics made from renewable resources can be naturally recycled by biological processes thus limiting the use of fossil fuels and protecting the environment.

Engineering thermoplastics vary in their tensile strength. 2 shows the effect of different ratios of bioplastic sheet towards the tensile strength. It was clear that the tensile strength and elongation at break of jackfruit seedsPP blends decreased from 1207 M Pa to 816 M Pa and 103 to 703 respectively.

33 tensile strength of bioplastic the following. Conference Series PAPER OPEN ACCESS Optimization of bioplastics tensile. School High Point University.

The lignocellulosic bioplastic demonstrates excellent mechanical properties with a high tensile strength of 128 MPa and toughness of 28 MJm 3 which are 7- and 8-times higher than cellulose. From FTIR analysis the absorption band of the CH and COH at 2932 cm 1 and 115292 cm 1 for the starch bioplastic shifted to lower Wavenumbers at 292631 cm 1 and 115154 cm 1 which is confirmed the. For the production of bioplastic.

View Optimization_of_bioplastics_tensile_strengthdocx from HISTORY AN AHA 102 at Maseno University. Tensile strength and elongation percent technique it was found that bioplastics were close to the standard ie in the sample 3 glycerol v v with a tensile strength of 464201 Mpa and percent elongation of 1515152 and a sample of 5 sorbitol v v tensile strength 314228 MPa and elongation percentage 1515152. The optimal conditions were 05 ml glycerin and 472 g corn starch with a tensile strength of 1718 Mpa.

D-Optimaly response was obtained by the value of the desirability function. The bioplastic prepared from banana peels that can be used as packaging material or as a carrying bag. Bioplastics are plastics derived from renewable feedstocks such as starch cellulose vegetable oils and vegetable fats.

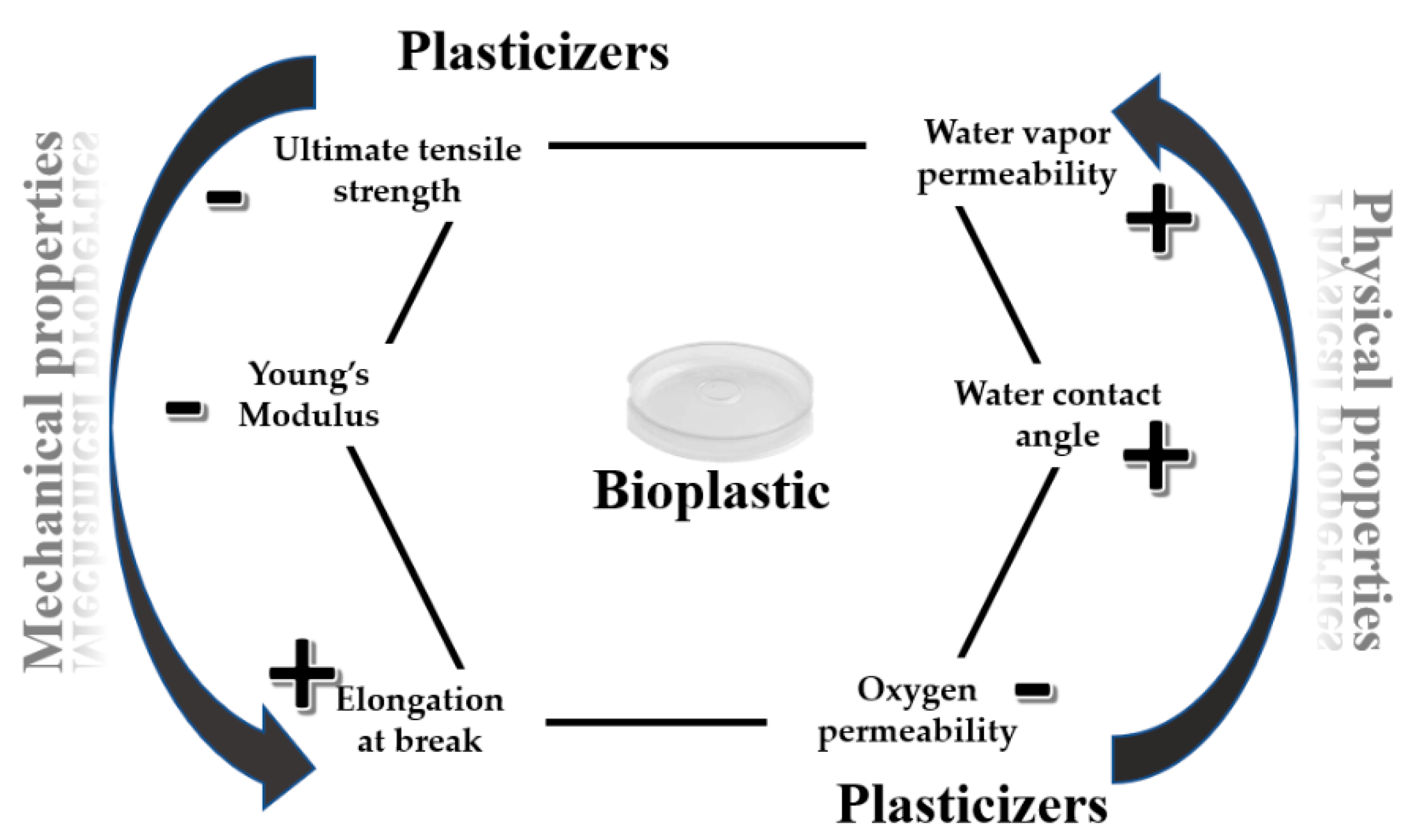

While the tensile strength on the DS of 11 was 657 MPa and the solubility and WVP did not change either. Morphology dynamic mechanical properties and tensile properties Youngs modulus tensile strength and elongation at break of the plastics were evaluated. The trend graph showed that potato-based bioplastic sheets R2 09413 has the highest tensile strength followed by cassava-based bioplastic R2 0904 sheet and corn-based R2 0882 bioplastic sheet.

33 Tensile strength of Bioplastic The following graphs shows the effect of. Export citation and abstract BibTeX RIS. Diagram of tensile strength test A.

Many commercial grades are specifically designed for thermoforming. The tensile strength in the bioplastics was only affected by the plasticizer showing a linear decreasing effect with reduction in the tensile strength with increasing glycerol concentration Eq. The culminating production of plastic is an estimated 78 billion tonnes as of 2015 Our World Data.

This figure showed that by increasing the amount of jackfruit seeds in the fabricated bioplastic the tensile strength and the strain percentage of bioplastic decreased accordingly. Things to note when considering Tensile or compressive strength Temperature Duration speed load and Structural requirements. Course Title BIO 1100.

Pages 7 This preview shows page 5 - 7 out of 7 pages.

The Mechanical Properties Of Bioplastic Graphene Oxide Composites Download Table

Tensile Strength Of Samples Of Cassava Starch Bioplastic With Calcium Download Scientific Diagram

Tensile Strength Of Bioplastics As A Function Of Amount Of Glycerin And Download Scientific Diagram

Tensile Strength Result Of Bioplastic Film Download Scientific Diagram

Tensile Strength Of The Bioplastic Film With Variation Zinc Oxide Filler Download Table

Tensile Strength Of The Bioplastic Film With Variation Zinc Oxide Filler Download Table

Tensile Strength Of Cellulose Bioplastic Bagasse Download Scientific Diagram

The Results Of Bioplastic Mechanical Properties Download Table

Tensile Strength Of Composite Bio Plastic In This Study Download Scientific Diagram

Shows The Results Of Tensile Strength And Elongation At Break As A Download Scientific Diagram

Pdf Properties Of Bioplastic Sheets Made From Different Types Of Starch Incorporated With Recycled Newspaper Pulp Semantic Scholar

Tensile Strength Of Various Bioplastics Download Scientific Diagram

Illustration Of Tensile Test On The Bioplastic Download Scientific Diagram

Testing Results Of Bioplastic Mechanical Properties Download Table

Tensile Strength Of Starch Based Bioplastic Reinforced With Mcc Avicel Download Scientific Diagram

Thermal And Barrier Characterizations Of Cellulose Esters With Variable Side Chain Lengths And Their Effect On Phbv And Pla Bioplastic Film Properties Acs Omega

Tensile Strength Of Various Bioplastics Download Scientific Diagram

Tensile Strength Mpa Of Biodegradable Plastic In Loamy Soil Download Scientific Diagram